Optimal Casting – Local Specification

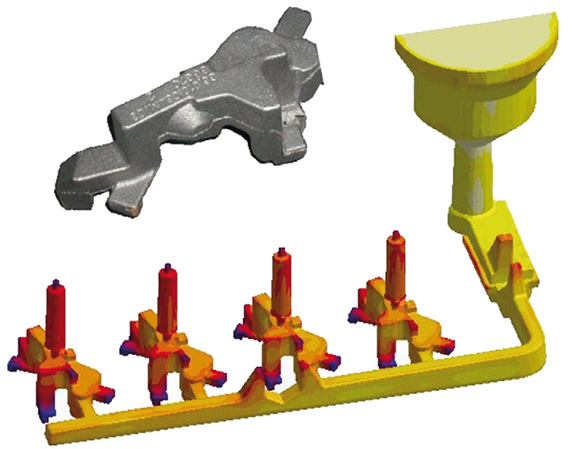

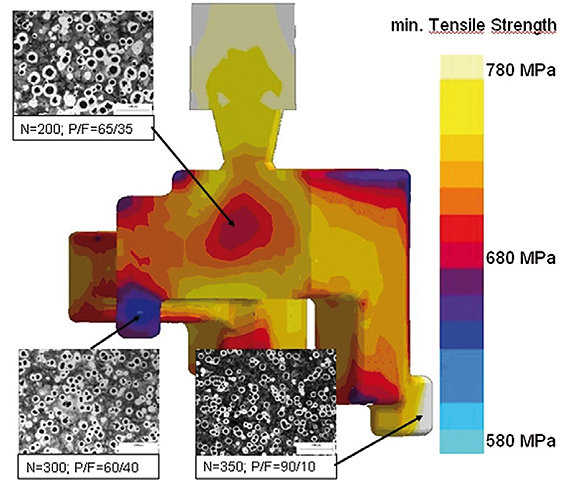

The gating and riser layout for this ductile iron casting was optimized with MAGMASOFT ®. The optimization target was simple and clear. A minimum of porosity and a minimum riser volume should be achieved at the same time. But, a real challenge was the definition of constraints for the optimization algorithm. Where in the casting do we need which microstructure (nodule count, pearlite/ferrite ratio) to fulfill the specification of 700 MPa tensile strength? What is the lowest acceptable and the highest allowed value?

Several optimization runs with different targets and constraints were conducted before it was finally understood and accepted by the designer that all optimization would lead to a compromise. Tensile strength between 580 MPa - 780 MPa in the critically loaded casting sections would be achieved, with an allowance for higher strength/lower ductility or lower strength/higher ductility sections where it would not harm the casting’s performance.

There was one important conclusion. It is easy to set an overall specification, but autonomous optimization shows that a compromise has to be defined instead.

* Courtesy of Heidelberger Druckmaschinen, Germany