Engine Blocks Full of Stress

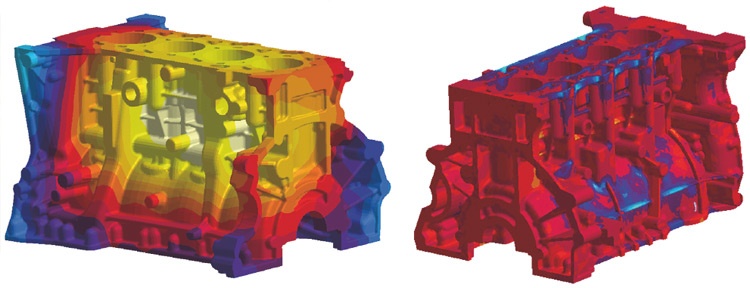

Cast iron engine blocks can be found in more than half of all passenger cars. Their performance and weight are, among other criteria, dependent on their geometry and the casting process, especially defects like porosity and residual stresses.

Only by using manufacturing process simulation, is it possible to determine the distribution of residual stresses in castings and to consider these properties in the design optimization process. Residual stresses develop during solidification and cooling of the casting due to uneven cooling rates in the different wall thicknesses.

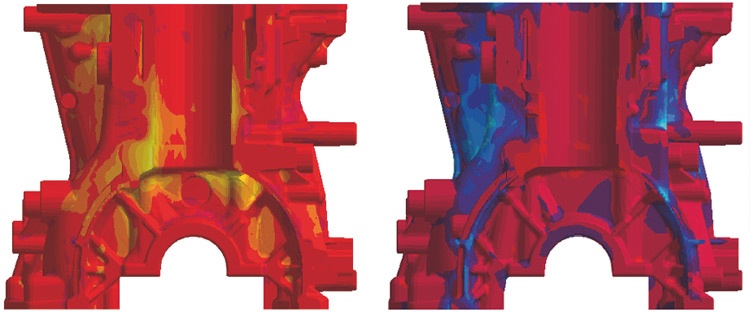

Tensile stresses, those stresses that are induced by “pulling”, may be critical during the manufacturing process, if their value exceeds the material’s tensile strength. By reaching this value, cracking occurs and the part fails. As a rule, tensile residual stresses are lower than this threshold value and the casting does not fail during the casting process.

Nevertheless, even if tensile stresses are below the critical value, the casting may fail during assembly, or even worse during driving.

Compressive stresses are the opposite of tensile stresses and are those stresses that are induced by pushing. It is unusual that compressive stresses are critical. One can try to use compressive stresses as a pre-loading, like in pre-tensioned concrete.

The biggest influences on residual stresses in castings are the design (80%) and the casting process itself (20%). To avoid problems, a manufacturing process simulation can be performed at an early stage of the design process, where geometric or casting process modifications may be made to decrease the level of tensile stresses. This approach leads to an optimized design and casting process of the engine block.

* Courtesy Ford Motor Company, Germany