MAGMASOFT® - A Trusted Engineering Tool Becomes an Indispensable Business Tool

Watry Industries has been a customer of MAGMA as a software user for over five years and, on a project-by-project basis, even longer.

Initially, Watry felt the expense of the software was a roadblock. Sales Manager Wayne Bennin, who was at Watry when they converted from using MAGMASOFT® on a project-by-project basis to being a licensed user, says, “The software was considered to be expensive and, before purchasing, it was hard for us to justify the cost savings of a problem that never occurred because we had already made the change that avoided the problem.” However, comparing the average number of trial and error runs prior to using MAGMASOFT® to the ones run after working with MAGMA on projects quickly eliminated that concern.

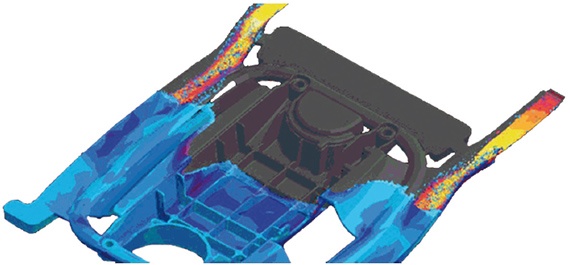

The Watry team immediately recognized the benefits of using MAGMASOFT®: not only was time saved, but value was added when they realized they could analyze a casting and go back to their customer with changes early in the process, avoiding problems later. They were impressed with the clear, concise way they were able to communicate the simulation results to their customers, benefitting not only the engineers and the quality department, but purchasing and the sales department as well. From the very beginning, Watry saw the software as a business tool, not just an engineering tool. “The expectation was always there for MAGMASOFT®’s effect to roll through the organization,” General Manager Jason Dannenberg explains.

Watry finds accurately simulating the entire casting process a huge advantage when communicating to customers why a design change is necessary. Customers find the software impartial, keeping the emotions out and making decisions based on facts. Watry’s customers recognize the need to run the simulation and are more apt to go along with design changes when presented with the simulation results.

“Having MAGMASOFT® cuts across all disciplines, whether it’s manufacturing, quality or sales and marketing. Even time spent in the tool room. Now, we have less and less rework of the mold needed before it makes a good part,” Dannenberg says.

Sales and engineering, as well as the quality department, have all seen the benefits in the decrease in lead times. All departments are positively affected by the reduction in time from inception of the project to completion of the part. Mike Kamin, Engineering Manager, says, “Lead time has definitely shortened, we spend more time up front, but we don’t sample three, four or five times before we get a quality part. We are more likely to make a good, quality part the first day it’s in the machine. It used to be we were a long way away from making a good part on the first day, pulling and making gating changes was very common. It just isn’t common anymore. The software gives us the opportunity to dig through a lot; everything from processing and moldmaking back to part design. It helps us really do some fine tuning to get to that ‘good part quality’ a lot more quickly and with minimal iterations.”

The foundry has gone back to parts they were producing for years and started running them through MAGMASOFT® to make them better and more up-to-date. Quality Manager Gary Haas adds, “There are many parts we make that have been around for a long time. What was good quality 5-10 years ago is not acceptable anymore, so we use MAGMASOFT® in a lot of retro jobs, as we go back and look at a part to see what improvements we can make.” Dannenberg adds, “We see MAGMASOFT® as an indispensable tool that Watry customers have come to expect. As a matter of fact, before having the license, it was the high level customers who own MAGMASOFT® themselves who mandated it back our way.

Watry has seen the benefits how the tool helps reduce the cost of their work, in general. Having the software changes how quality functions overall and, most importantly, it reduces scrap. Sales sees process simulation as a necessity, not an option. It separates Watry Industries from their competition. It reduces costs overall, while strengthening ties with customers, as the foundry is perceived as being more forward-thinking and tech savvy.

General Manager Jason Dannenberg concludes, “Having MAGMASOFT® helps highlight deficiencies organizations experience out on the factory floor. If you say you are going to do something for a customer, you must do it. MAGMASOFT® helps you ‘grow-up’ as an organization. It helps identify critical characteristics that must be met. Continuously using MAGMASOFT® teaches us more about the moldmaking and casting process. It helps us understand which parameters of the process will greatly affect the outcome of the quality of the part.”

Watry Industries (Sheboygan, WI, USA) has grown from a small facility, started in 1957 by Mr. Nic J. Watry, into one of the most automated, high-tech, permanent mold foundries in the industry. Processes offered are CAD design for molds, fixtures, and specialty equipment for secondary operations, building of this tooling and equipment, permanent and semi-permanent mold casting, heat treating, precision machining, powder coating, pad printing, and sub-assembly, all performed in-house by Watry.