Problem Corrected – Case Solved

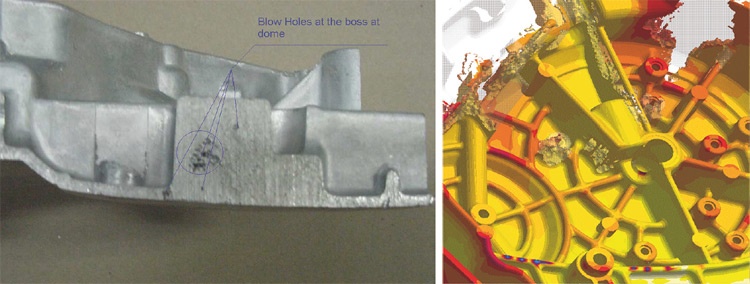

An HPDC client in India who is a large manufacturer of motorcycles and scooters for both domestic and export markets, experienced porosity problems with a cast component from one of their suppliers after machining the casting on the top side.

Simulation indicated that a vertical rib directly under this feature was responsible for allowing metal to very quickly fill through the vertical ribs and swirl around the circumference of the shaft before entrapping air in the thick wall sectional.

To solve the problem, the middle ingate was modified by placing an “island” in front of it to divert the melt flow away. Further simulations showed that this island did divert the flow, but that wasn’t enough. Only changing the design itself in this area led to a reduction in metal speeds flowing along the vertical wall.

The communication between foundry and designer, and the changes agreed upon by both sides, completely solved the problem.