Solving Hard Drive Housing Problems

A medium-sized Japanese foundry located south of Kuala Lumpur in West Malaysia specializes in the casting of hard disk drives for desktop and laptop computers of various manufacturers.

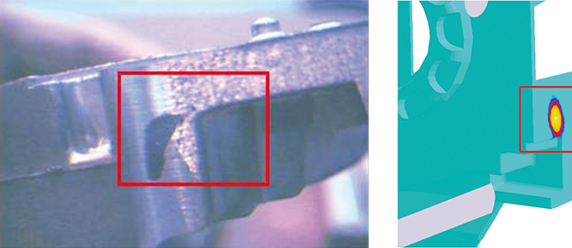

In their production of about half a million disk drives per week, one of their 3.5 inch components had a high scrap rate for various reasons including incomplete filling, solidification shrinkage in the side walls, and surface blisters found on one side of the two-cavity die.

Five different modifications were investigated using simulation before the dies were modified. The first simulations of the existing process showed a good comparison with reality in that both surface blisters and incomplete filling could be shown.

The first modification was to shorten the gate to direct the metal toward the center instead of the side walls and avoid incomplete filling. The blisters were addressed by changing the thickness of the bridge. The shrinkage issues were solved by redirecting the cooling channels to increase cooling of the thick side wall, as well as spot cooling on both sides of the die insert. The initial scrap rate of up to 15 % was reduced to around 0.5 % using this approach.