Optimization of Ingot Quality Using Evolutionary Algorithms

Petr Kotas, MAGMA Giessereitechnologie GmbH, Tomáš Huczala and Bohuslav Chmiel, Třinecké železárny, a.s., Jesper Henri Hattel, Technical University of Denmark

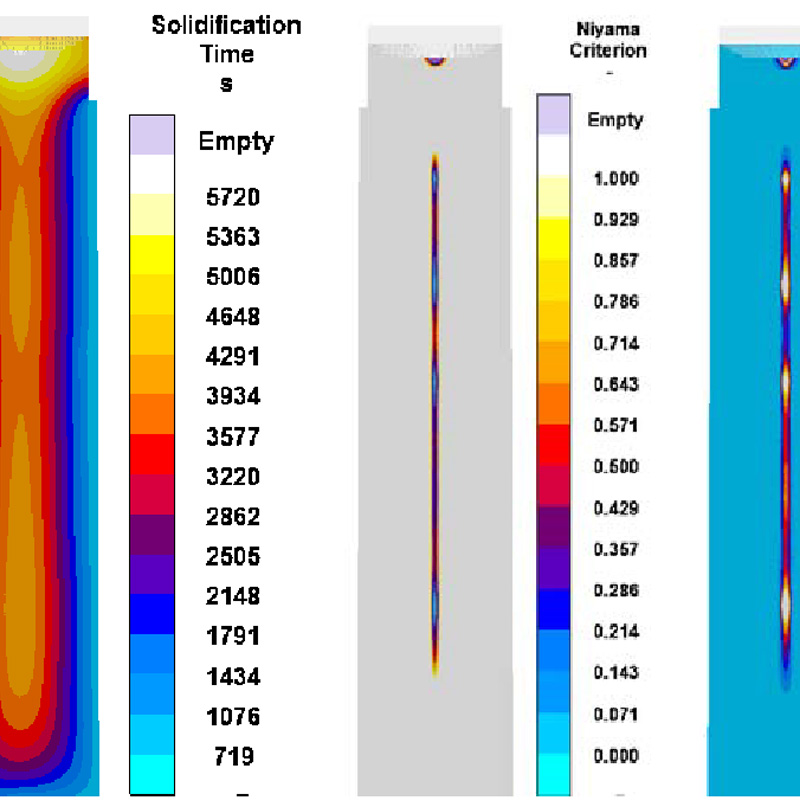

This paper presents findings and results of a fully coupled 3-D numerical simulation of the manufacturing process of a three ton large steel ingot. Simulation of the teeming process as well as several thermal criterion functions together with solidification calculations are utilized for predicting the occurrence and distribution of various casting discontinuities and defects such as shrinkage and centerline porosity inside the considered ingot. The original ingot layout and its process parameters are then subjected to fully automated computer optimization. This is accomplished by coupling the casting simulation software package MAGMASOFT® with an optimization engine based on genetic algorithms. The simulation package is used as a virtual experimentation field in which the optimizer varies process parameters or design features and in this way tries to find the optimal route to satisfy the given objective(s). Several parameters can be modified and evaluated independently of each other. The optimizer tries to find the best compromise to the given (mostly conflicting) objectives using simulations based on validated physics. This not only further reduces the need for physical trial runs to find the optimal process window, but allows for the detailed evaluation of many process parameters and their individual impact on providing a robust process. An optimization case is considered in which unknown optimal process parameters and boundary conditions, i.e. initial pouring temperature, pouring conditions, interface heat transfer coefficients, together with shapes and sizes of the hot top, its insulation and the mould taper, are sought using multi-objective genetic algorithms. All this is done in order to establish a more directional and progressive solidification and better thermal conditions inside the ingot to minimize the aforementioned defects.

Please read the complete publication in the linked PDF.