Core and Mold Sand Simulation

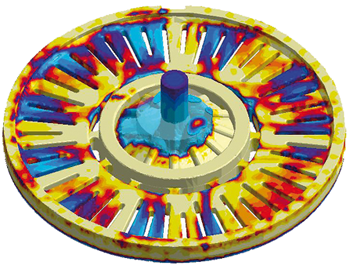

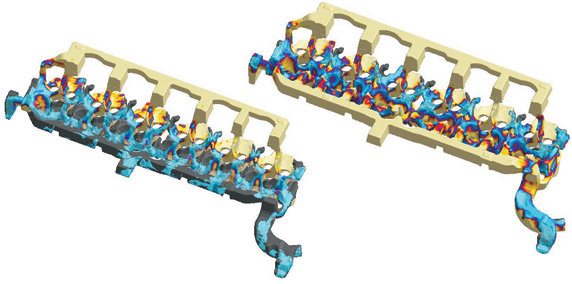

With increasing demands on casting quality and a tendency to thinner-walled structures for high performance components, the production of the corresponding cores has become a limiting factor for casting quality and productivity. The lifetime of a core can be investigated using simulation to optimize the process and core layout.

The most important core production processes are core shooting and hardening of the binder. Using simulation, changes in core filling patterns and sand densities during core shooting can be virtually observed for different blow tube/vent configurations or shot pressures/times. By simulating the gasing of the core, the transport of curing gases like amine for cold box binders or the drying of inorganic binders can also be visualized for varying processing conditions.

During the casting process, the binder pyrolyzes and emits gases. Simulation shows which pressures arise in the core during casting and where these gases are transported, whether into the casting to cause defects or into the atmosphere as a source of pollution.

Sand simulation developments have now closed a missing link in the chain of casting process simulation.