Keeping Thin-Walled Castings Straight

Through the production of complex, thin-walled structural castings in light alloys, the foundry industry has been in a position to substitute castings for components that were classically sheet metal fabrications. These structural parts are characterized, in addition to their geometric complexity, by the requirements on strength and ductility they must fulfill. One of the biggest challenges in the production of such components is keeping within the dimensional tolerances, which is often only possible through expensive straightening.

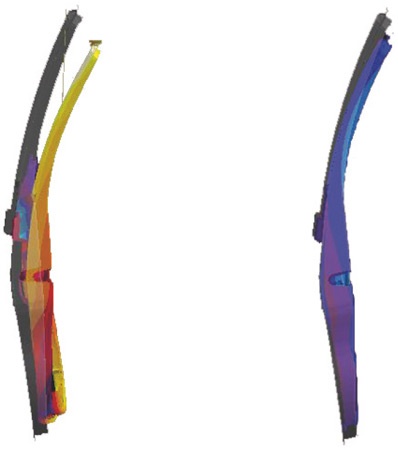

The large number influencing factors makes mastering distortion of the part extremely complex. This requires a careful selection of all process parameters as well as, if need be, the design of a rack for holding the component during heat treatment. With the help of process simulation, the distortion during each of the processing steps can be calculated and its sources determined. Simulations at an early stage of the design process can be used to determine whether the required tolerances can be achieved through an optimal process layout or whether design changes are necessary.

* Courtesy of Volkswagen AG and Georg Fischer Automotive, Germany