Bending the Pattern Rules at Bonds

There are many defects and problems that can scrap a casting - methods engineers spend their working lives trying to find casting techniques that avoid them.

One of the most delicate and hard-to-solve issues relates to castings that are bent! Anyone who has made a casting knows that the dies or patterns do not have the same shape as the casting that comes out. Pattern makers and tooling companies deliberately modify the dimensions of the final desired casting shape when deciding on the size and shape of the pattern and tool, based largely on experience. Often an acceptable final casting shape and size are achieved. But it would save some metal and machining if we could find the pattern shape that would give the exact size and shape of casting we wanted: Bend the pattern, to straighten the casting.

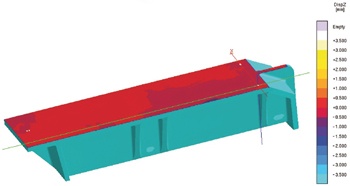

Bonds Foundry Co. Ltd of Tow Law, County Durham, England, had made blast furnace throat armor segments for many years, with the casting coming out bent and the top face being ground flat, at significant cost. With the use of MAGMASOFT®, Bonds Foundry was able to straighten the casting and their bottom line. The ‘straight’ geometry was first simulated and the flatness of the top surface assessed. The prediction of distortion showed a bow of around 7 mm, - 3.5 in the middle and + 3.5 on the ends. The question is, ‘what shape of ”bent” pattern gives a straight casting?’ MAGMAstress and MAGMApost can show distortion with a magnification factor, to exaggerate the bend and visualize it more easily (see also this issue’s MAGMAtip). By using a negative distortion factor, the ‘inverse’ or opposite bend can be viewed and the geometry of the ‘inverse bend’ can be exported from MAGMApost. This bent geometry can then be used in a second MAGMASOFT® simulation. The casting may not come out completely.

The images above show the simulated distortion from the 1st version and the inverse bent geometry, which was exported from MAGMApost and used for the 2nd version. After 3 simulation loops, a top surface flatness of ± 0.35 mm was achieved compared to the original ± 3.5 mm. This is manual optimization, but given enough loops we should eventually find a mold cavity shape that gives the casting shape we want. It should be noted that we may find a flat top face but also find distortion in other areas of the casting. Bonds first modified the existing pattern. After sampling several castings confirmed the results, they made a new ‘bent’ pattern.

The cost implications were significant, as all castings made on the old pattern were ground flat, but from the new pattern the casting were flat straight out of the mould, all meaning savings in time and money.