Two for One

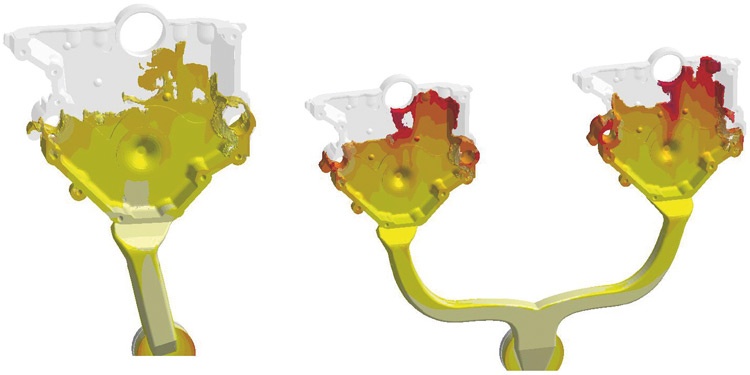

The productivity of the casting of a cover was to be improved. Originally, the part was produced using a single cavity die and fulfilled all quality requirements. To increase productivity, a change to a twocavity die was wanted, without making any compromises regarding casting quality.

To maintain the casting quality, both cavities in the dual-cavity die should be filled as similarly as possible to the flow in the single cavity die. Since simulation delivers a quantitative description of the flow for each simulated variant, it provides an ideal tool for making this kind of comparison.

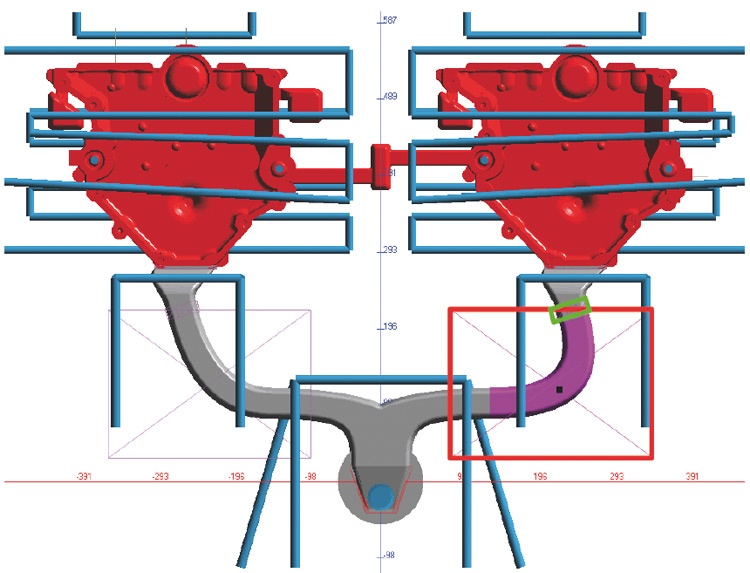

The flow is primarily influenced by the geometry of the runners and gates that direct the metal into the casting, meaning that these geometries needed to be optimized to give the desired flow pattern.

Autonomous optimization in MAGMASOFT® allows the simulation of a large number of configurations until a specified objective is reached. Using ptimization, a layout for a two-cavity die was found which enabled production with the same quality as with the original single cavity die – and at double the productivity!

* Courtesy: Ford Motor Corporation, Cologne, Germany