No Time to Lose

Tick tock, tick tock ... A glance at the clock shows us how quickly time flies. Technological change provides even more speed. Numerous tasks need to be completed at the same time. This increases the pressure on everyone to deliver the best quality in the shortest possible time – and this is also the case in the foundry industry.

Especially when it comes to casting processes, many things need to be planned and coordinated in parallel. This is because changing one process parameter can affect many different aspects of casting quality. It is therefore a major challenge to optimize the casting process by evaluating the final casting quality while simultaneously pursuing quality and cost objectives. This is especially true for steel castings with their great diversity of grades, resulting microstructures and properties, and the multiple manufacturing steps for achieving the required quality – from metallurgy and casting, up to heat treatment and machining.

Pinar Foundry has been using MAGMASOFT® in product planning for a long time. Ever since the possibilities of Autonomous Engineering have become available, experts have been systematically using this methodology in process planning for testing different variants and quantitatively evaluating the results in terms of quality and costs.

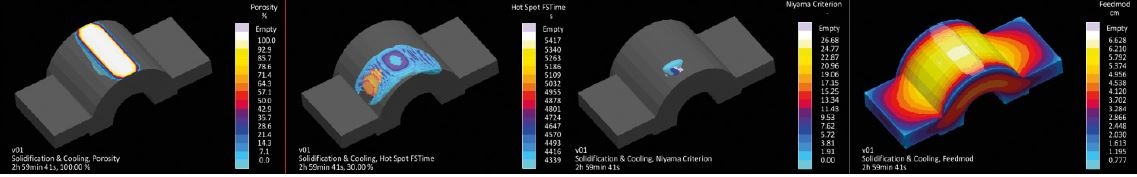

Different configurations of feeders and chill concepts were analyzed for a GS20Mn5 steel casting with a part weight of 875 kg (Figure 1). The objective was to achieve the best compromise between the required casting quality (here: shrinkage defects) and maximum yield.

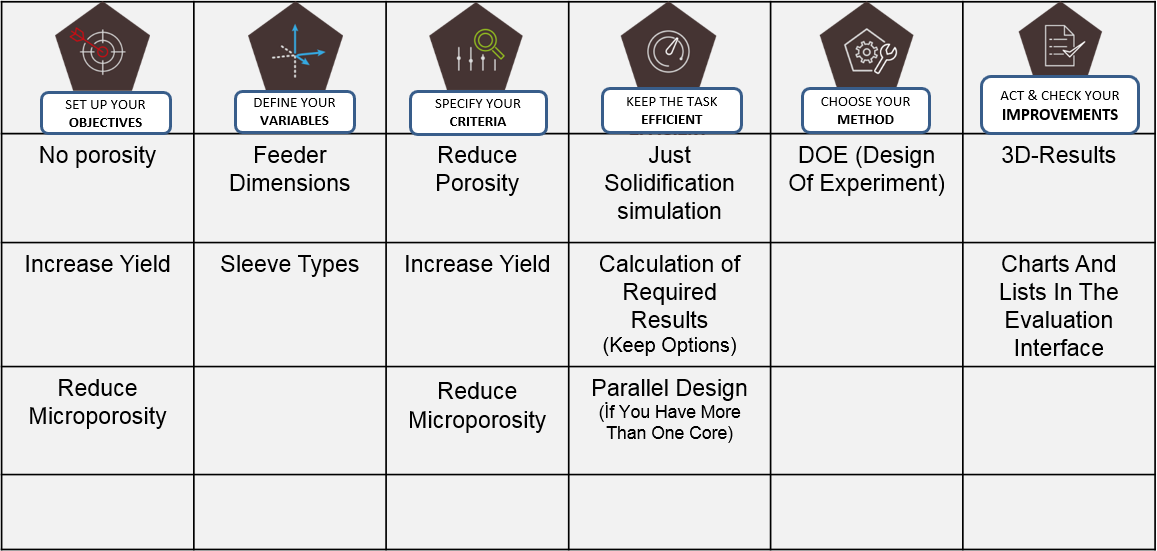

The engineers at Pinar Foundry used the MAGMA APPROACH to establish a systematic evaluation for an optimized and robust casting design. Figure 2 shows how, in this project, the MAGMA APPROACH helps to define variables, quality criteria as well as the method to achieve the objectives as efficiently as possible.

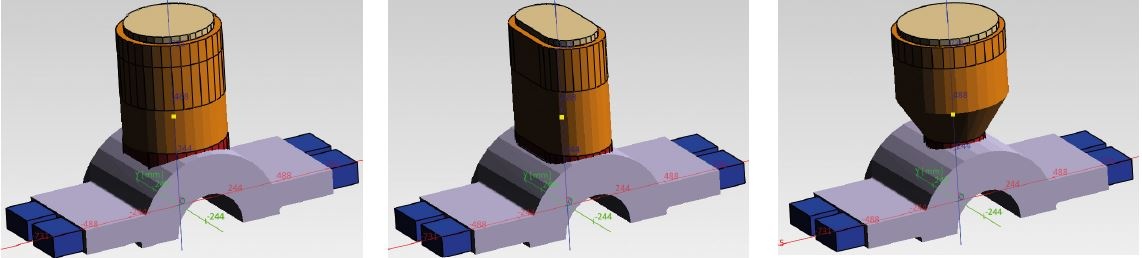

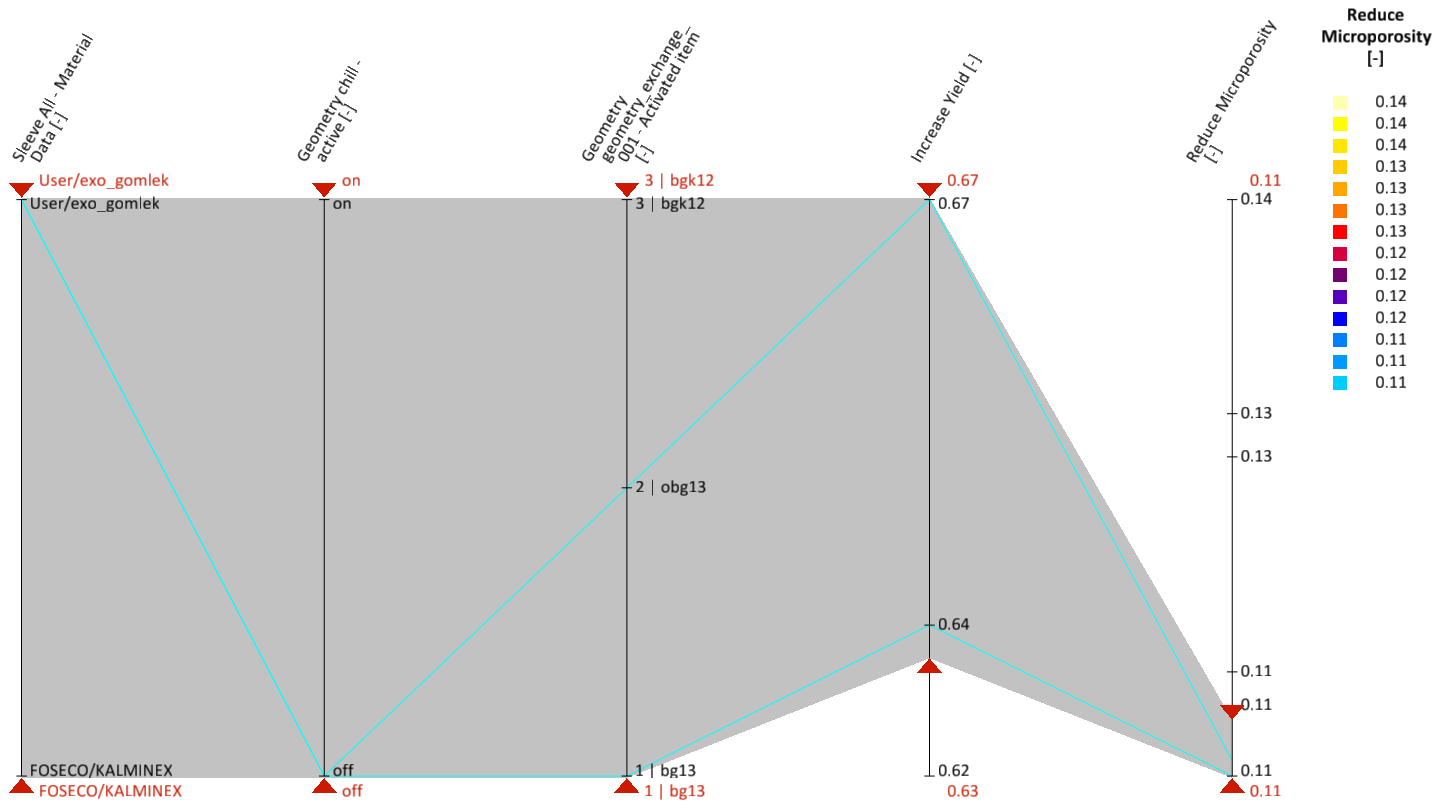

The geometry exchange feature in MAGMASOFT® was used to vary type, number and position of the feeders. For this purpose, three feeder shapes – cylindrical, oval and conical –, two different feeder sleeves and two different chill configurations were selected (Fig. 3). This led to 12 designs autonomously run by the software. The parallel coordinate plot helped to evaluate the impact of the variations on shrinkage porosity and casting yield, Figure 4.

The cylindrical feeder provided the best results, with the lower chills needing to be active. Several steel castings were successfully manufactured under these conditions (Figures 5a and 5b). The color penetration test applied to the raw and machined part confirmed that the design decisions were right, Figures 5c and 5d.

Courtesy of Pinar Foundry

About Pinar Foundry

Pinar Foundry, founded in Izmir in 1979, is one of the most experienced foundries in Turkey. They are specialized

in the production of alloyed heat and wear resistant steel castings, which are mainly used in the cement industry, mining crushers, as well as machinery and valve industries. Advanced casting quality, machining capabilities and the use of MAGMASOFT® are only part of what makes Pinar Foundry unique in the steel casting industry in Turkey.