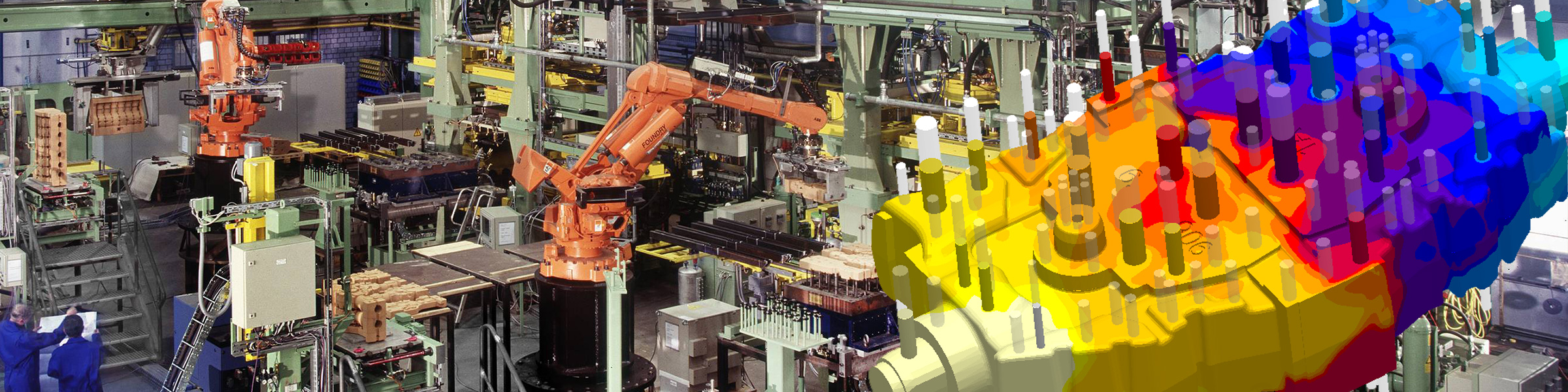

砂芯和模具 可预测的制芯过程

芯盒设计、生产效率、射砂/吹气和固化的循环生产条件以及随之产生的砂芯性能都影响着砂芯的质量和经济性。

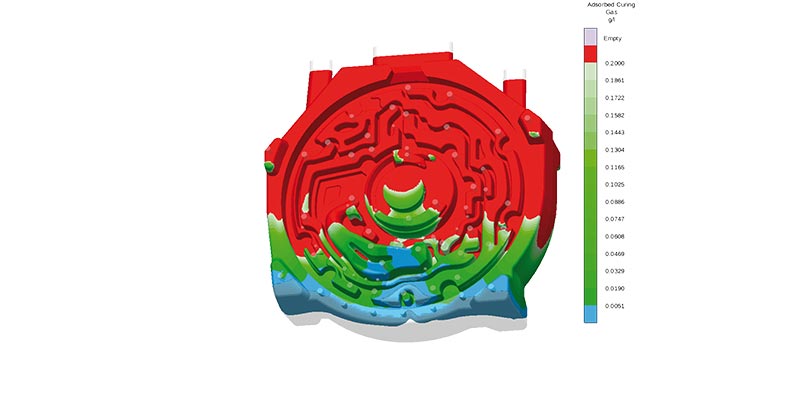

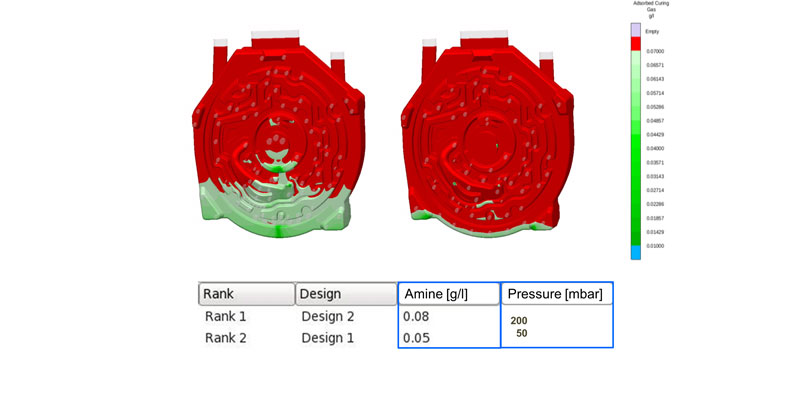

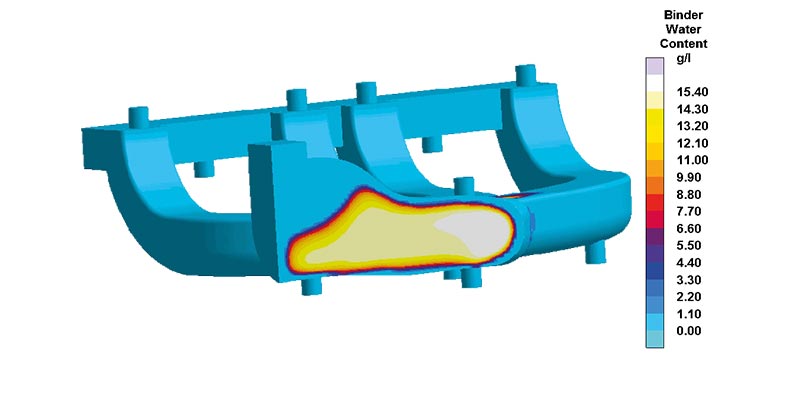

MAGMA C+M 能自动确定砂芯生产(包括制芯、冷热芯盒用有机和无机粘结剂的吹气和固化)的稳健工艺条件和最优解决方案。这一设置虚拟试验设计并自动评估结果的综合工具,帮助模具生产者和砂芯生产者确定最优设计和工艺条件,并提供如下的支持:

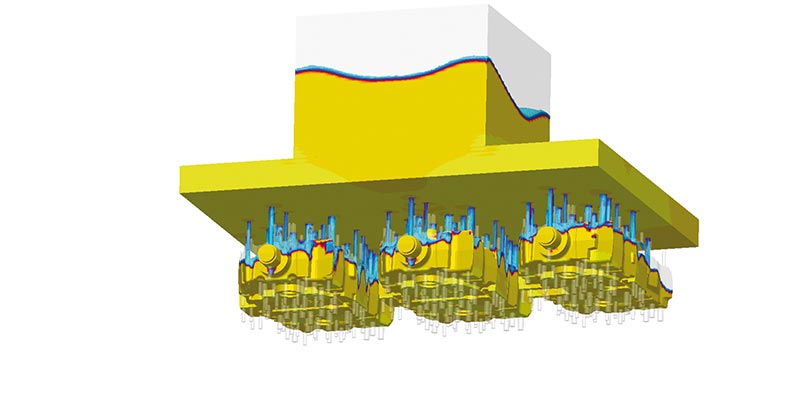

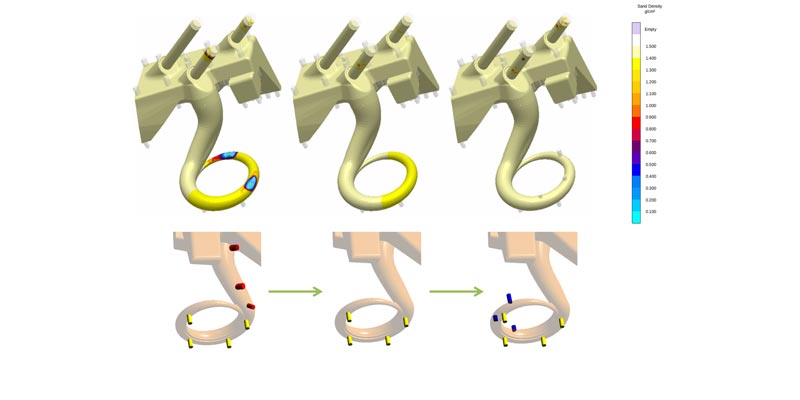

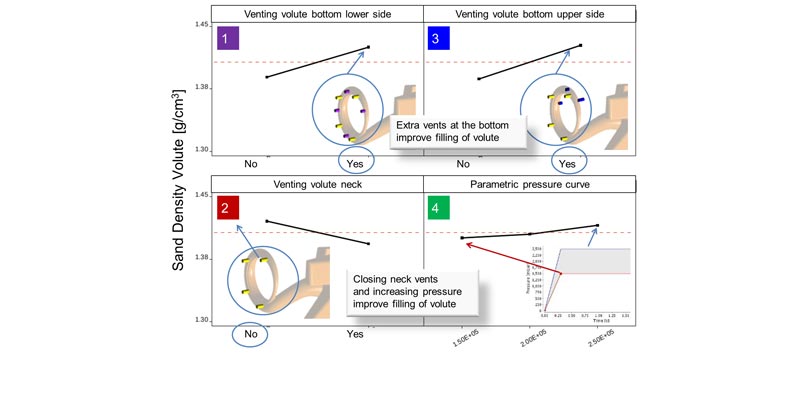

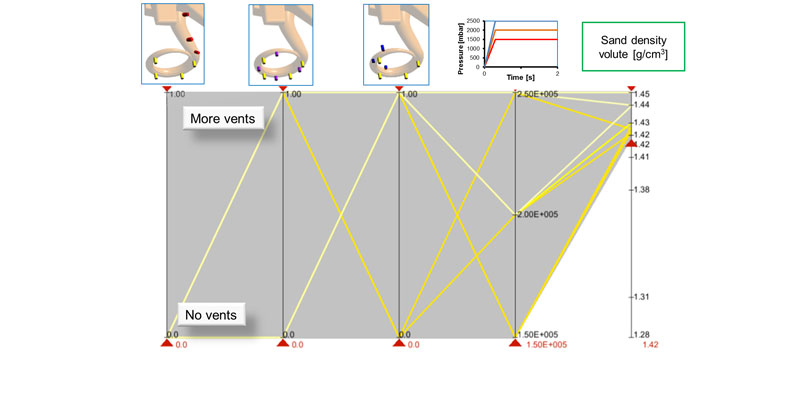

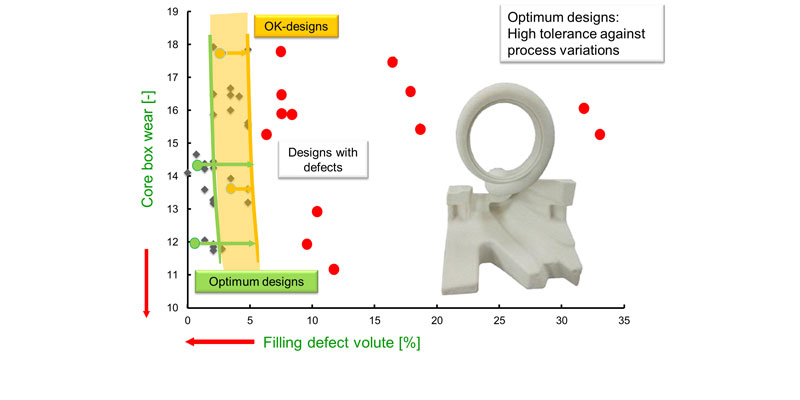

- 通过优化射嘴和排气的工艺分布来取得稳健的设计以及低的模具磨损

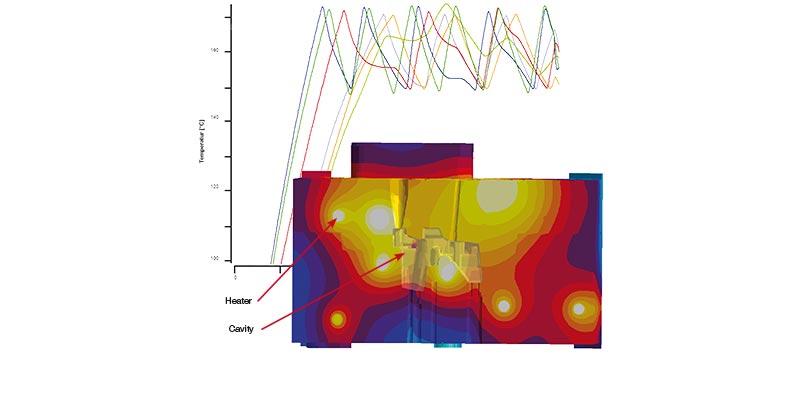

- 通过验证芯盒加热装置,确定需要的固化时间

- 为了实际的循环生产, 以实践为导向来确定制芯和吹气的稳健工艺参数

- 降低粘结剂含量和胺的消耗量

- 避免在车间厂房内进行大量试验和芯盒改造

MAGMA C+M的虚拟试验设计和自主优化的独特综合方法使得软件自动运行不同的芯盒设计以及参数组合方案。MAGMA C+M有助于确定符合要求的工艺条件。它可以考虑影响砂芯质量的所有因素,快速全面地实现不同的目标。

这使得MAGMA C+M 成为模具生产者和砂芯生产者布置最优工艺设计、实现可靠生产过程、尽量减少质量风险、确定稳定工艺方案和实现原材料和生产过程无经济风险的关键所在。

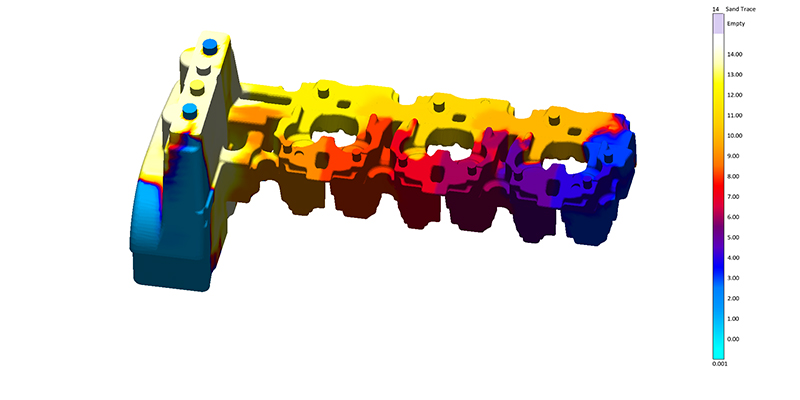

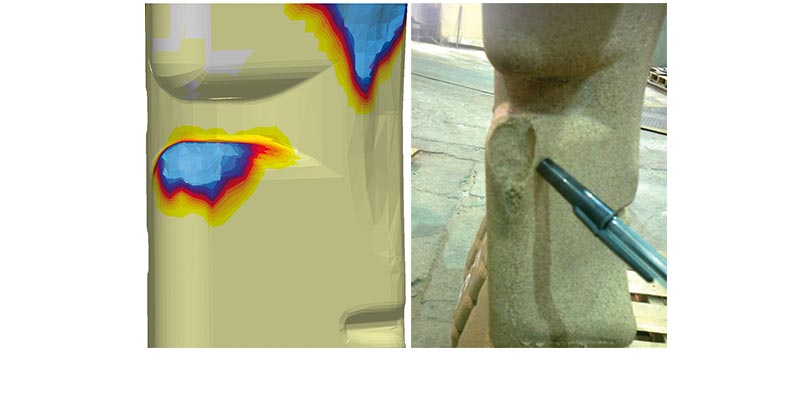

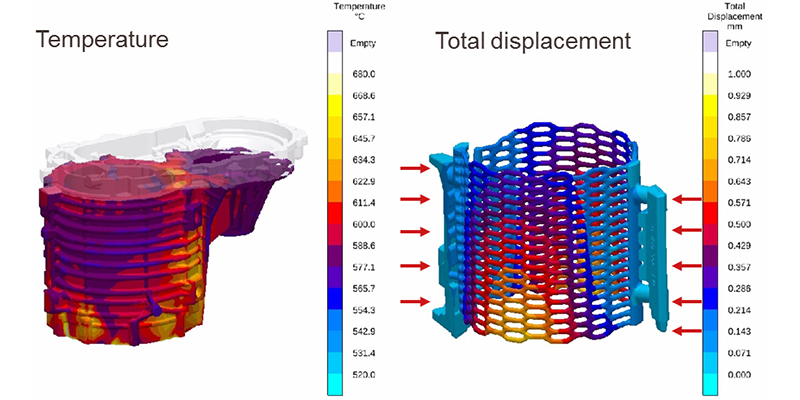

MAGMAinteract® 总位移

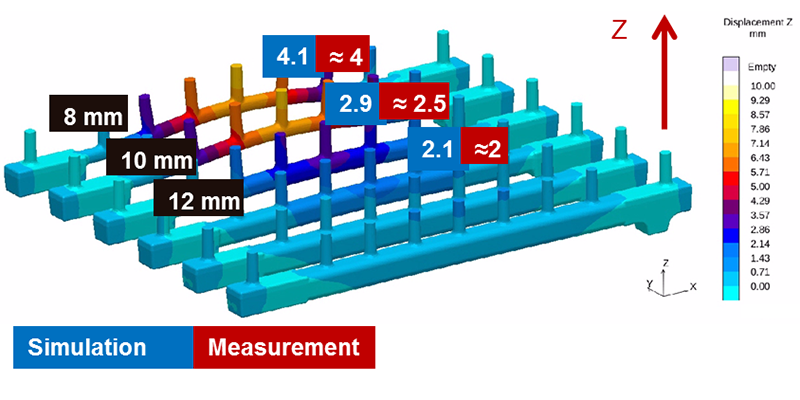

MAGMAinteract® Displacement Z

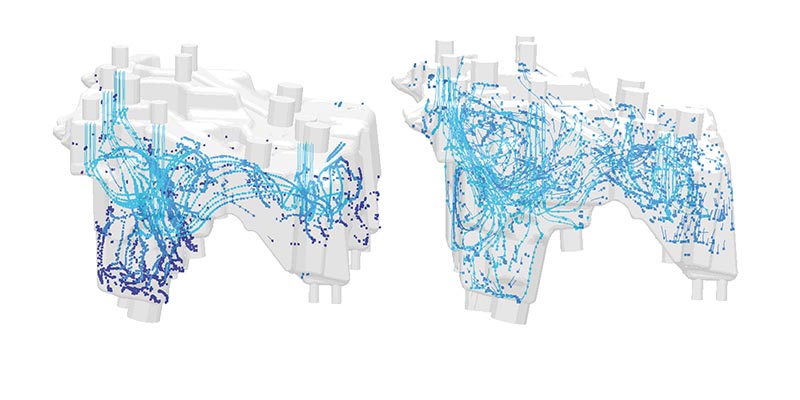

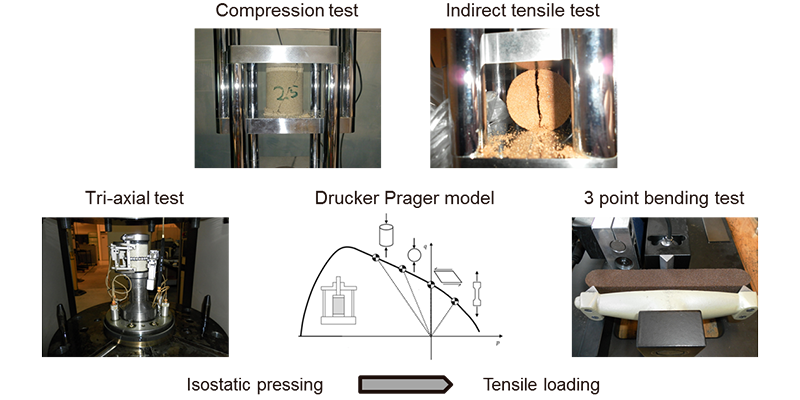

Detailed knowledge of bonded sand, from measurements to new mechanical model, validated on benchmark examples and used on complex cores

Multi-state material from a loose granular material to a bonded porous material, where strength is governed by binder bridges and contact between grains

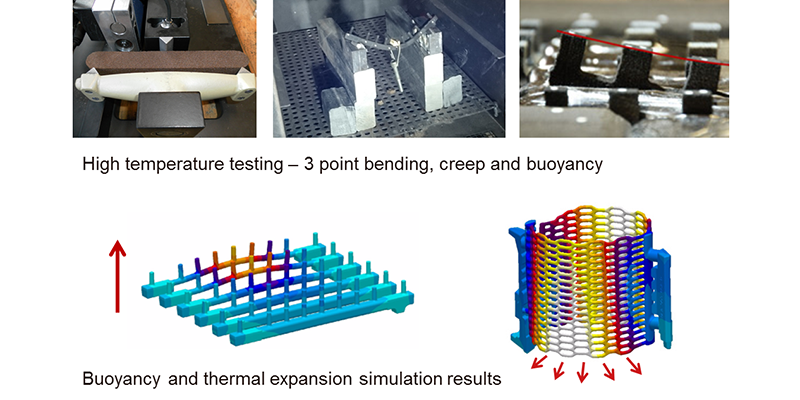

Bending of long cores due to buoyancy can now be simulated and analyzed

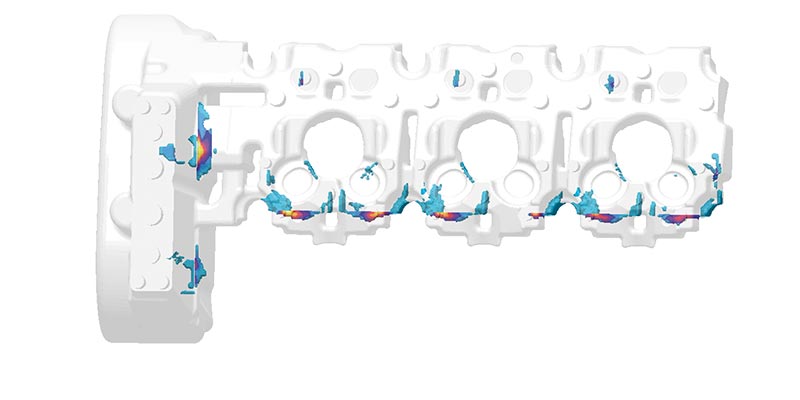

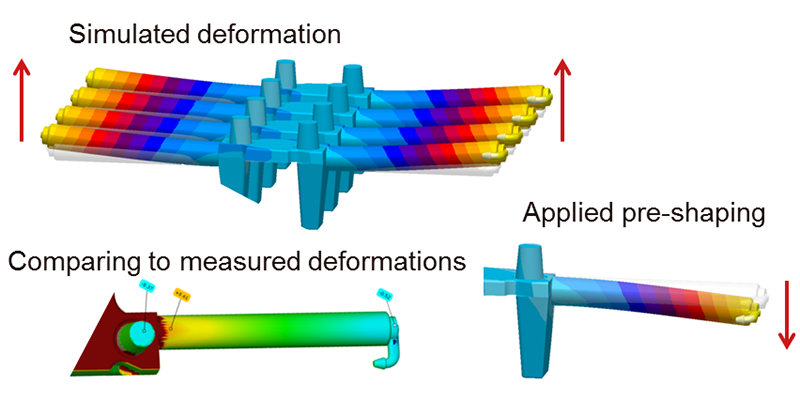

Core distortion modeling is fully coupled to the filling and solidication simulation allowing the user to optimize the entire process to minimize core distortion and related issue of dimensional tolerances in the casting.

Simulation results are used to pre-shape the core to meet tolerance requirements of the final part.

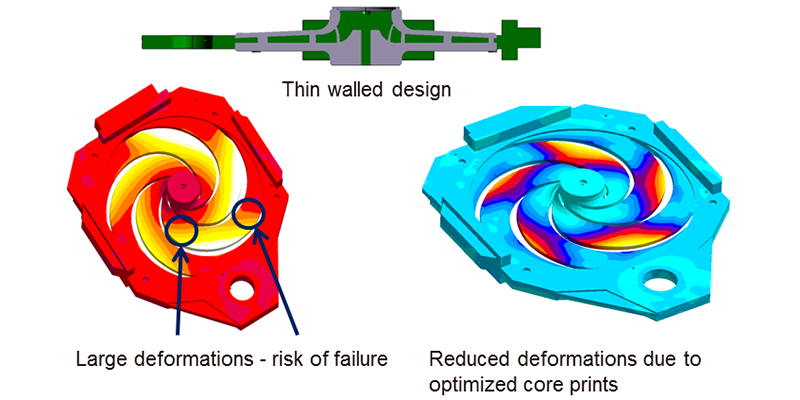

Location of core prints are optimized to avoid problems in thin walled designs