定向热处理

在铸造过程后,很多铸件需要进行热处理,以获得期望的金相和机械性能。在MAGMASOFT®的热处理模块中,根据如下参数计算出各热处理步骤中铸件内的温度分布:

- 热处理炉温度

- 工艺时间

- 工艺温度

- 淬火介质和温度

热处理工艺的虚拟优化可以:

- 减少炉内的工艺时间

- 评估热处理的需求以满足金相、残余应力分布或机械性能的要求

- 分析工艺变化对金相和材料性能的影响

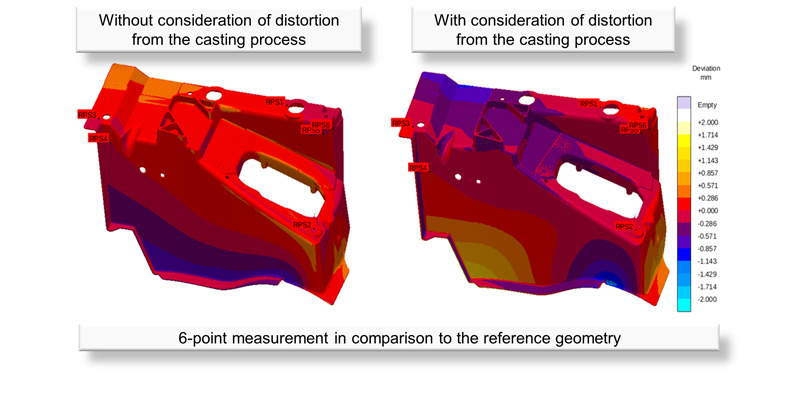

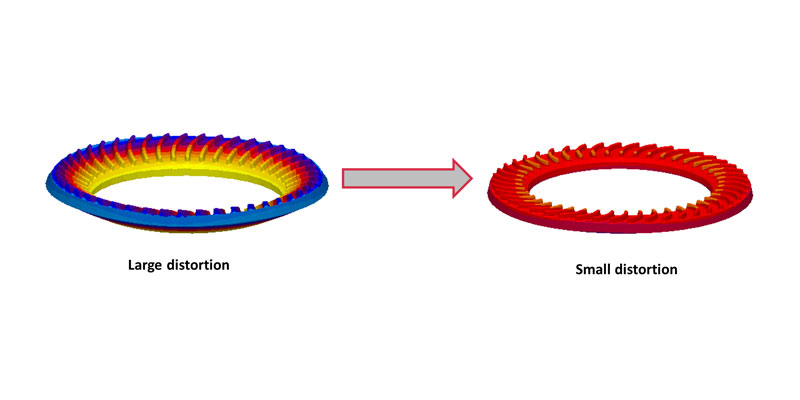

- 尽量减小热处理过程中的铸件变形

- 减少大量试验的成本和开发时间

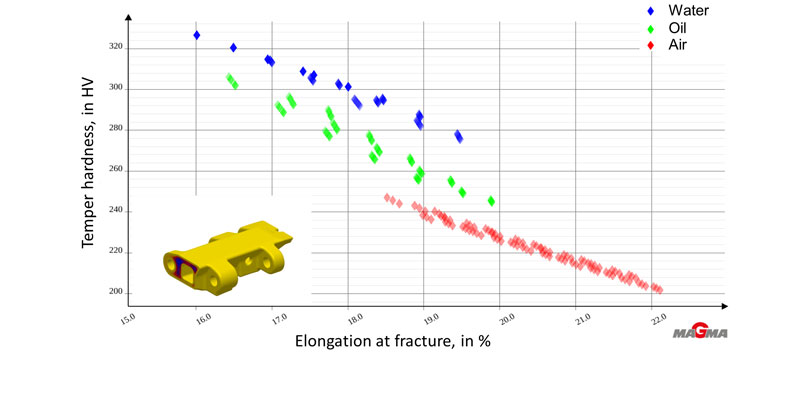

虚拟试验可以实现铸钢件回火温度和时间的系统变化,以找到强度和延展性之间的最优平衡。

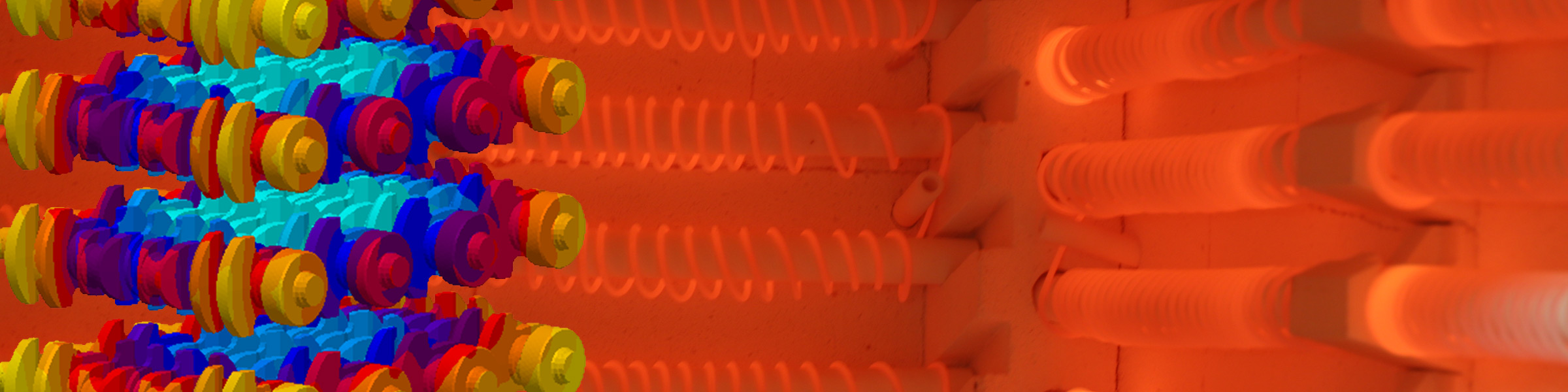

可计算铸造过程中残余应力的释放,例如可以进行铸铁件的去应力退火。在铸铁中,除了常规去应力退火和珠光体化外,还可以优化复杂生产工艺,以生产出奥贝球铁(ADI)。

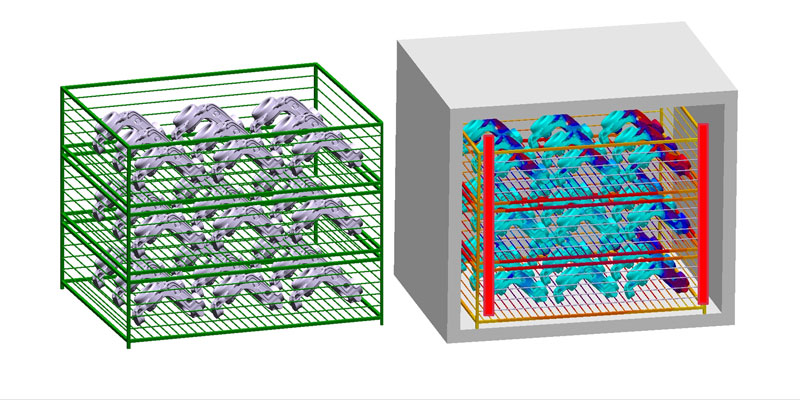

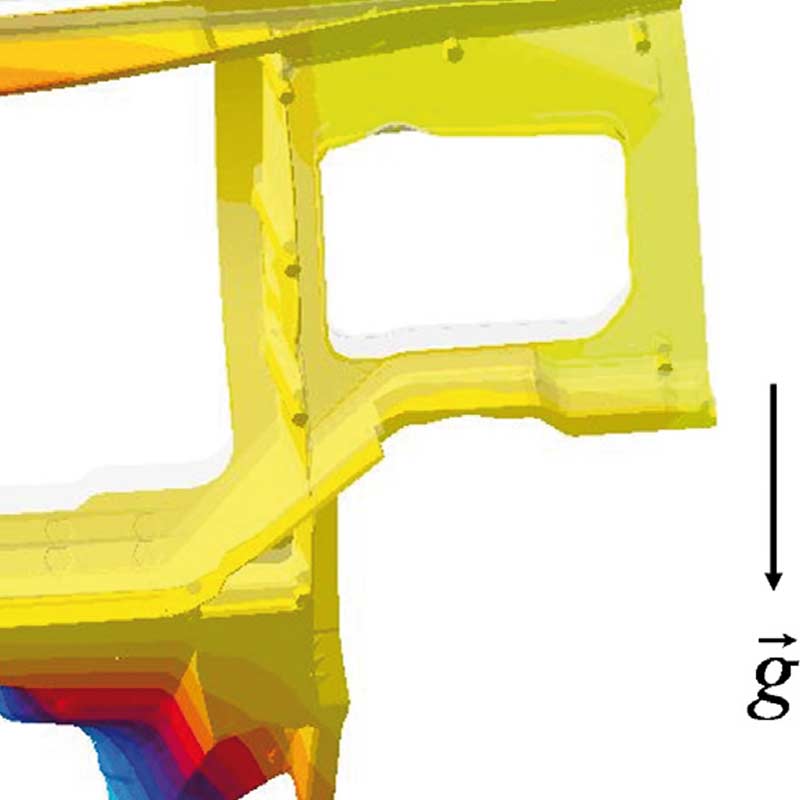

对于由铝合金的结构件,除了其他方面外,还可借助于热处理过程中残余应力计算对热处理支座的设计进行优化。

通过相应的工艺和设计优化,可以将由于铸件淬火时较高的温度梯度导致裂纹的风险降到最小。

热处理工艺的虚拟优化可以:

- 减少炉内的工艺时间

- 评估热处理的需求以满足金相、残余应力分布或机械性能的要求

- 分析工艺变化对金相和材料性能的影响

- 尽量减小热处理过程中的铸件变形

- 减少大量试验的成本和开发时间

虚拟试验可以实现铸钢件回火温度和时间的系统变化,以找到强度和延展性之间的最优平衡。

可计算铸造过程中残余应力的释放,例如可以进行铸铁件的去应力退火。在铸铁中,除了常规去应力退火和珠光体化外,还可以优化复杂生产工艺,以生产出奥贝球铁(ADI)。

对于由铝合金的结构件,除了其他方面外,还可借助于热处理过程中残余应力计算对热处理支座的设计进行优化。

通过相应的工艺和设计优化,可以将由于铸件淬火时较高的温度梯度导致裂纹的风险降到最小。